ORDER A “CUSTOM BUILT†HYDRAULIC PUMP“Assemble to Order†means you can choose a basic pump with gas, air or electric motor. Then select the proper valve, gauge, pressure control, motor control and reservoir. You get a two-stage pump that gives high oil volume for fast cylinder approach (and return with double-acting cylinders) in the first stage and high pressure in the second stage.

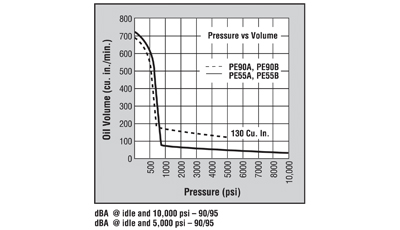

1.) 1 1/8 HP UNIVERSAL MOTOR

These motors start under full load and are suitable for operation up to 5,000 or 10,000 psi. The motor is 1 1â„8 hp, 12,000 rpm, 115 or 230 volt (specify), 50/60 cycle A.C. single phase (25 amp draw at 115V.). With proper valve they can be used with single- or double-acting cylinders. Remote control available.

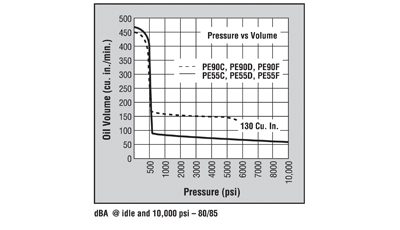

2.) 1 1/2 HP JET MOTOR, SINGLE & THREE-PHASE

Feature low noise level, moderate speed for long service and are ideal for fixed applications. Motor is 1 1â„2 hp, 3,450 rpm, 115 or 230 volt, 50 or 60 cycle (specify), A.C. single phase with thermal overload switch. Can be used with single or double-acting cylinders and equipped with remote control. Also available in 230/460 volt, three-phase (specify).

NOTE: These do not start under full load unless valve is in “neutral†(requires open or tandem center valve) and are not recommended for frequent starting and stopping.

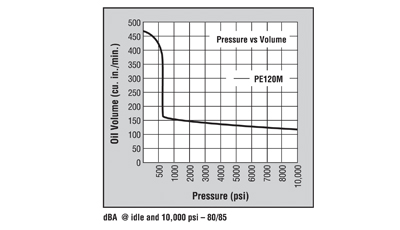

3.) 3 HP JET MOTOR, THREE-PHASE

Gives low noise level and long life due to its moderate operating speed. Ideal for fixed installations. Consists of basic 10,000 psi pump, jet pump motor: 3 hp, 3,450 rpm, 230/460 volt, 60 or 50 cycle (specify). A.C. threephase, with thermal overload switch. Equipped with internal and external relief valve. Will start under load.

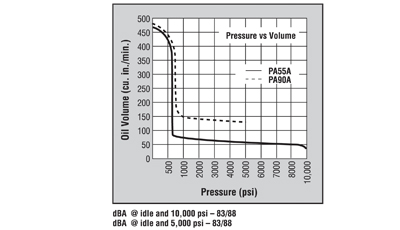

4.) 3 HP AIR MOTOR

This pump is ideal for use where electricity is unavailable or cannot be used. The 5,000 or 10,000 psi pump has a 3 hp air driven motor at 3,000 rpm (optimum performance based on 80 psi air pressure and 50 cfm at the pump). You can drive single- or double- acting cylinders with the correct valve.

NOTE: 80 psi air supply required to start under full load.

5.) GASOLINE ENGINE

This version is perfect when electricity and air are unavailable. It is capable of continuous operation at full pressure. Consists of basic 10,000 psi pump, 4-cycle Briggs & Stratton “Diamond Edge†gasoline engine, developing 6 hp. As with all these pumps, this unit can be valved for use with either single- or doubleacting cylinders.

HOW TO ORDER YOUR « CUSTOM » HYDRAULIC PUMP… »You can choose from pre-engineered, off-the-shelf components to customized your pump. All the components are listed in table form, with key letters or numbers in ‘Specifications’. Complete instructions guide you so you can determine what is needed to complete a pump assembly. Shown below is an example of a custom-built pump.

Pump No. PE55A-VV-Z-G-A-A-A-A-D-BB-C-2F is a 10,000 psi two-speed pump with a 115 volt, 50-60Hz, single phase, 1 1/2 hp, 12,000 rpm motor; a 9512 4-way solenoid valve with a 202778 remote hand control, a 9041 pressure gauge, no gauge accessories, standard pressure control, standard On-Off-Pulse motor control, 400630OR9 2-gallon reservoir, a 350431 fluid level/temperature gauge, 10494 casters, and 2 gallons of standard hydraulic oil.

TO BUILD YOUR PUMP, FILL IN KEY LETTERS FROM CHARTS

| 1. Basic Pump | 2. Select Valve | 3. Select Valve Control | 4. Select Gauge | 5. Select Gauge Accessories | 6. Pressure Control |

|---|---|---|---|---|---|

| 7. Pressure Switch | 8. Motor Control | 9. Reservoir | 10. Level/Temp Gauge | 11. Choose Casters | 12. Select Oil |

Use the charts numered from 1-12 below to select the pump, valve, gauge and other accessories to suit your needs. For the pump, fill in the basic number plus key letter in block 1 above and the key letter only in the blocks 2-12 above for any of the other items. Refer to the appropriate web pages for more specific information on the products you need.

1. BASIC PUMP

| Basic Pump Numbers | Specifications Note: Customer must specify voltage required. |

|||||||

|---|---|---|---|---|---|---|---|---|

| PE55 (10,000 psi) |

PE90 (5,000 psi) |

PE120 (10,000 psi) |

PA55 (5,000 psi) |

PA90 (5,000 psi) |

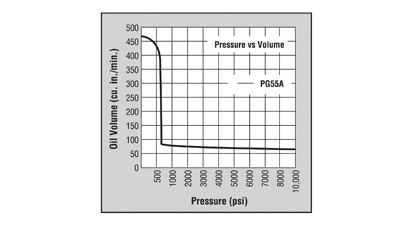

PG55 (10,000 psi) |

Power Source | rpm | hp |

| A or AC* | A or AC* | 115V-60 Hz, 1Ø | 12,000 | 1 1/8 | ||||

| 110V-50 Hz, 1Ø | 12,000 | 1 1/8 | ||||||

| B or BC* | B or BC* | 230V-60 Hz, 1Ø | 12,000 | 1 1/8 | ||||

| 220V-50 Hz, 1Ø | 12,000 | 1 1/8 | ||||||

| †C or CC* | †C or CC* | 115V-60 Hz, 1Ø | 3,450 | 1 1/2 | ||||

| †C50 | †C50 | 110V-50 Hz, 1Ø | 2,850 | 1 1/2 | ||||

| †D or DC* | †D or DC* | 230V-60 Hz, 1Ø | 3,450 | 1 1/2 | ||||

| †D50 | †D50 | 220V-50 Hz, 1Ø | 2,850 | 1 1/2 | ||||

| †F60 ** | †F60 ** | 208, 230/460V-60 Hz, 3Ø | 3,450 | 1 1/2 | ||||

| †F50 ** | †F50 ** | 220/380V-50 Hz, 3Ø | 2,850 | 1 1/2 | ||||

| M60 ** | 208, 230/460V-60 Hz, 3Ø | 3,450 | 3 | |||||

| M50 ** | 220/380V-50 Hz, 3Ø | 2,850 | 3 | |||||

| A | A | Air Motor | 3,000 | 3 | ||||

| A | Gas Engine | 3,600 | 6 | |||||

| *Suffixes AC, BC, CC & DC indicate pumps for Canadian orders only. NOTE: All electric units have 24 volt secondary circuit. **Specify voltage required. †These pumps do not start under full load unless valve is in “neutral†position (requires open or tandem center valve) and are not recommended for frequent starting and stopping. |

||||||||

2. VALVE

| Manifold/Manual/Air Operated Directional Valves | Function | Manifold/Manual/Air Operated Directional Valves | Function | ||

|---|---|---|---|---|---|

| AB | 9628Â manual, tandem center | 4-way, 3 pos.valves | O | 9609Â manual, pressure compensated flow control | 3-way, 4 pos. |

| AC | 9632Â manual « twin » tandem and open center | R | 9506Â manual, tandem center Posi-Check* | 4-way, 3 pos. valves | |

| A | None | — | RR | 9511 manual, open center | |

| B | 9626 manifold | Manifold 3-way, 2 pos. valves | S | 9500Â manual, tandem center | |

| C | 9584Â manual | T | 9507Â manual, closed center « Posi-Check* » | ||

| D | 9582Â manual | U | 9501Â manual, closed center | ||

| E | 9610Â automatic, pilot operated | FF | 9569 solenoid operated -24 volt | 3-way, 2 pos. | |

| G | 9504 manual | 3/4-way, 2 pos. valves | Solenoid Operated Directional Valves | Function | |

| JJ | 9594 air operated | HH | 9572 solenoid operated -24 volt | 3/4-way, 2 pos. | |

| L | 9502 manual, closed center « non-interflow » | 3-way, 3 pos. valves | PP | 9599 solenoid operated -24 volt | 3-way, 3 pos. |

| M | 9520 manual, tandem center « Posi-Check* » | VV | 9512 solenoid operated -24 volt | 4-way, 3 pos. valves | |

| N | 9576 manual, metering tandem center | Â | WW | 9615 solenoid operated -24 volt | |

3. VALVE CONTROL

| Valve Remote Control | Use with Valve | Â | Valve Remote Control | Use with Valve | ||

|---|---|---|---|---|---|---|

| A | None | – | Z * |

202778 remote hand control, 10 ft. | 9512 or 9615 | |

| X * |

304718 remote hand control, 10 ft. | 9572 | ZF * |

309653 remote foot control, 10 ft. | 9512, 9615, 9569 or 9599 | |

| XF * |

309652 remote foot control, 10 ft. | 9572 | ZZ ** |

209593 remote hand control, 12 ft. | 9594 | |

| Y* | 202777 remote hand control, 10 ft. | 9569 or 9599 |  * Solenoid & Motor Control  ** Remote Air Motor Controls | |||

4. PRESSURE GAUGE

| Pressure Gauges | |

|---|---|

| A | None |

| B | Other – Specify. |

| G* | 9041 0-10,000 psi – 0-689 Bar (2 1â„2″ dia.) |

| H* | 9040 0-10,000 psi – 0-689 Bar (Liquid) (2 1â„2″ dia.) |

| J* | 9051 0-10,000 psi – 0-689 Bar (4″ dia.) |

| M* | 9052 0-10,000 psi – 0-689 Bar (Liquid) (4″ dia.) |

| Â * Analog Gauges | |

5. GAUGE ACCESSORIES

| Gauge Accessories | |

|---|---|

| A | None |

| N | 9049 pulsation dampener – All dry gauges |

6. PRESSURE CONTROL

| Pressure Control | |

|---|---|

| A | With standard external pressure regulator |

| C | Other – specify |

| D | 350199 premium external pressure regulator. See Product No. 9633 for details. |

7. PRESSURE SWITCH

| Pressure Switch | |

|---|---|

| A | None |

| B* | 9625 electric pressure switch (500-10,000 psi) NOTE: Pressure switch is factory pre-set at 10,000 psi unless otherwise specified. |

| C** | 9641 pilot operated air control valve – N.C. |

| D** | 9643 pilot operated air control valve – N.O. |

| Â * Pressure Switch ** Pilot Operated Air Control Valve | |

8. MOTOR CONTROL

| Electric Motor Controls | |

|---|---|

| A | Standard On/Off/Pulse control (does not include remote switch) for A, B, C, D, F and M electric pumps. Also used for remote controlled solenoid valves. |

| B | None |

| C* | 25017 remote motor hand switch, 10 ft. |

| D* | 203225 remote motor hand switch, 10 ft. |

| E* | 10461 remote motor foot switch, 10 ft. |

| Air Motor Controls | |

| AA | Other |

| B | None |

| P | 27876 hand motor control (for PA55 & PA90 series) |

| Q | 27877 foot motor control (for PA55 & PA90 series) |

| Â * On/Off Motor Control | |

9. RESERVOIRS

| Reservoirs | Capacity | |

|---|---|---|

| A | None |  – |

| B | Other – Specify |  – |

| D | 40063OR9 – PE55, PE90, PE120, PA55 and PA90 series | 2 1/2 gal. |

| E | 61165†– PE55, PE90, PE120, PA55 and PA90 series | 2 gal. |

|  | (Oil temperatures in excess of 150° F. may cause permanent failure of the thermoplastic reservoir) |  |

| F* | RP22†– PE55, PE90, PE120, PA55 and PA90 series | 2 1/2 gal. |

| H | 61799OR9 Same as D except with drain port |

2 1/2 gal. |

| J* | RP50 – PE55, PE90, PE12, PA55 and PA series | 5 gal. |

| K | 40137OR9 – PG55 series | 5 gal. |

| P | 209124 – PE55, PE90, PE120, PA55 and PA90 series | 7 gal. |

| V* | RP100 – PE55, PE90, PE120, PA55 and PA90 series | 10 gal. |

| W* | RP101 – PG55 series | 10 gal. |

| NOTE: Includes cover adapter and misc. accessories when applicable.  †High density polyethylene.  ‡ Aluminum.  * Large Capacity Reservoirs |

||

10. FLUID LEVEL/TEMPERATURE GAUGE

| Fluid Level/Temperature Gauge | |

|---|---|

| A | None |

| BB | 350431 fluid level/temperature gauge |

11. CASTERS

| Casters | |

|---|---|

| A | None |

| C | 10494 caster for use with 40063OR9 reservoir (Specify quantity of four) |

12. OIL

| Oil | |

|---|---|

| E | Ship pump without oil |

| F* | 9637 1 gal. standard hydraulic oil |

| G* | 9638 2 1â„2 gal. standard hydraulic oil |

| Q* | 9639 1 gal. Flame-Out hydraulic oil |

| R* | 9640 2 1â„2 gal. Flame-Out hydraulic oil |

| U* | 9645 1 gal. biodegradable hydraulic oil |

| V* | 9646 2 1â„2 gal. biodegradable hydraulic oil |

| NOTE: Select type of hydraulic oil and specify quantity. Â * Hydraulic Oil |

|

Go to Accessories section for product detail:

Hydraulic Pump Accessories:

- Air Filter/Regulator/Lubricator

- Casters

- Fluid Level / Temperature Gauge

- Foot Control Guard

- Gauges – Analog

- Gauges -Â Accessories

- Hydraulic Oil

- Large Capacity Reservoirs

- Magnetic Strip

- On/Off Motor Control

- Pilot Operated Air Control Valves

- Pressure Regulator

- Pressure Switch

- Pump Mounted Subplates

- Remote Air Motor Controls

- Solenoid & Motor Control

| Catalog | |