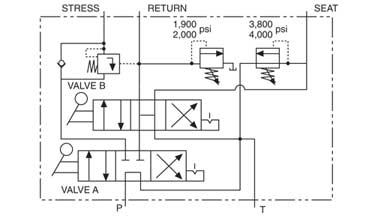

Application – Multi-strand, double-acting stressing jacks with an auxiliary seating cylinder.

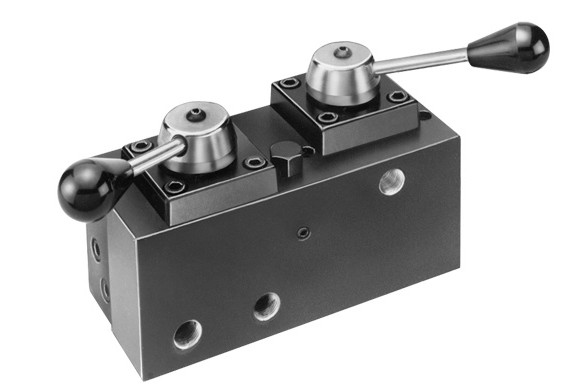

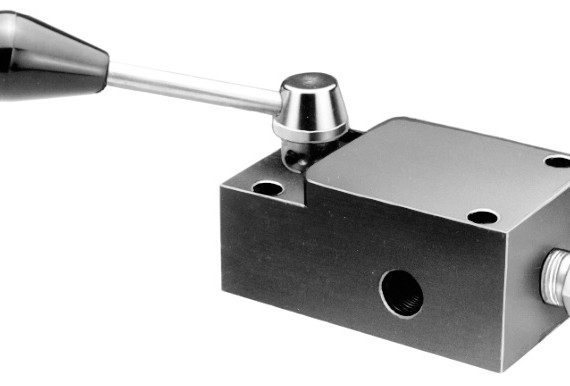

Actuation – Dual lever operated, detent positioned.

Operation –

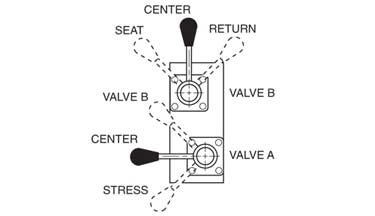

- With valves “A†and “B†in center position, pump is started; cable is inserted into stressing tool.

- Valve “A†is placed in “Stress†position; cylinder extends to tension cable. Pump pressure controls force exerted by tensioning cylinder in this position. “Stress†port is checked internally, and can only be released by building pressure in the valve “B†return position.

- When desired cable tension is achieved, valve “A†is placed in valve “B†position and valve “B†in “Seat†position. Seating portion of cylinder will be pressurized to seating pressure controlled by “Seat†relief valve (factory set to 3,900 psi).

- Valve “B†is shifted to “Return†position, which is pressure controlled and will not exceed 2,200 psi. “Return†portion of stressing tool should be pressurized and will release “Stress†port when pressure reaches 15% of “Stress†port pressure.

- “Stress†port will remain open and cylinder will return as long as pressure differential is maintained. “Stress†and “Seat†ports are open to reservoir.

- When cylinder has fully returned, both valves are shifted to “Center†position and oil will be directed to reservoir. Maximum pressure setting for the “Seat†relief valve is 6,000 psi.

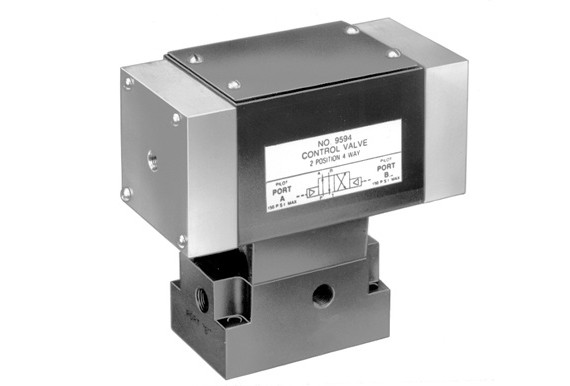

Used on these pumps: PA17*, PA46*, PA55, PE17*, PE21*, PE30, PE46*, PE55, PE84, PE120, PE200, PE400, PG30*, PG55, PG120, PG400, PQ60 and PQ120 series.*

* These pumps may have reduced first flow stage characteristics due to internal valve restrictions.

CAUTION: To prevent sudden, uncontrolled descent of a load as it is being lowered, use a Load Lowering Valve (No. 9596) or Counter Balance Valve (No. 9720) in conjunction with the directional valve used in your application.Â

IMPORTANT: Conversion kit 251528 must be used when mounting any of the valves on PA17 or PE17 pumps.

IMPORTANT: When ordering any valve for a PE30 or PG30 series pump, ½†longer mounting screws are required.

For valves 9504, 9584, 9610 and 9610A, order four 12001 cap screws.

For valve 9582, order two 12001 and two 10856 cap screws.

| Order No. | Cylinder Application * |

Operation | Valve Type | Volt | Advance/ Return | Advance / Hold Return | Posi-Check® Feature | Weight (lbs.) |

|---|---|---|---|---|---|---|---|---|

| 9632 | S.A. & D.A. | Manual | Post Tensioning | — | Special | No | No | 13.6 |

| * “S.A.†represents single-acting cylinders, “D.A.†represents double-acting cylinders | ||||||||

Pump mounted, 6-position detented 5-way manual dual valve. Rated pressure to valve « A » is 10,000 psi and valve « b » is 6,000 psi. Case pressure is 500 psi max.

| Catalog | |

| Operating Instructions | |

| Parts List | |