Designed for use up to 10,000 psi with hydraulic jacks, cylinders, etc. They are the threaded union type for interchanging cylinders in seconds. Each half is valved with a precision ball for a tight shutoff when disconnected. These couplers also permit the separation of cylinders or hose from pump when at 0 psi with minimal oil loss.

NO-SPILL, PUSH-TO-CONNECT HYDRAULIC HOSE COUPLERS

Designed to permit high oil flow, the no-spill, push-to-connect couplers with locking collar and flush face design are for high pressure applications. The flush-face concept makes it easy to clean both coupler ends before connecting. Our unique push-to-connect, “dry-break†design eliminates oil spillage. The locking collar makes accidental disconnects a thing of the past. For 10,000 psi operation.

HYDRAULIC COUPLER DUST CAP

Dust cap fits either male or female half couplers.

| Order No. | Description | Weight (lbs.) |

|---|---|---|

| 9795 | Complete quick coupler, 3/8″ NPTF. (Includes two 9800 dust caps). | 0.8 |

| 9796 | Female (cylinder) half coupler with No. 9800 dust cap, 3/8″ NPTF. | 0.5 |

| 9796-E | Same as 9796, but with EPR seals. | 0.6 |

| 9796-V | Same as 9796, but with Viton seals. | 0.6 |

| 9797 | Optional metal dust cap (cylinder half). | 0.1 |

| 9798 | Male (hose) half coupler (less hose half dust cap), 3/8″ NPTF. | 0.3 |

| 9799 | Optional metal dust cap (hose half). | 0.1 |

No-Spill, Push-to-Connect Hydraulic Hose Couplers

| Order No. | Description | Weight (lbs.) |

|---|---|---|

| 9792 | Female (cylinder) half quick coupler only. | 0.3 |

| 9793 | Male (hose) half quick coupler only. | 0.3 |

| 9794 | Complete quick coupler (male and female). Dust caps not included. | 0.5 |

Hydraulic Couplers Dust CapÂ

| Order No. | Description | Weight (lbs.) |

|---|---|---|

| 9800 | Dust cap. For male or female 3/8″ NPTF half couplers. | 0.3 |

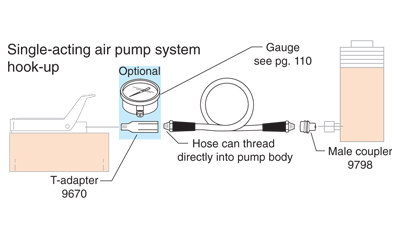

To Connect:

Simply align the tip and body coaxially and smoothly push until the body sleeve slides forward, signaling connection. Rotate the sleeve 90° to engage the sleeve-lock to prevent accidential disconnection.

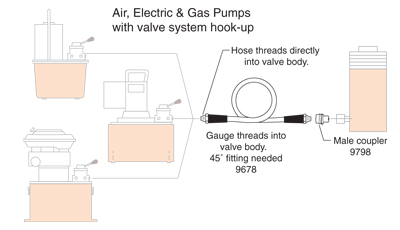

To Disconnect:

Align the notch in the body sleeve with the ball pressed into the outside surface of the body. Pull the sleeve back. The tip will eject from the body due to spring force. Manually pull the halves apart if they do not fully separate due to spring force alone. Disconnection under pressure must be avoided.

| Catalog | |

| Parts List | |